Transport solutions

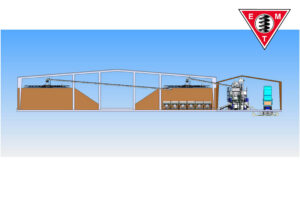

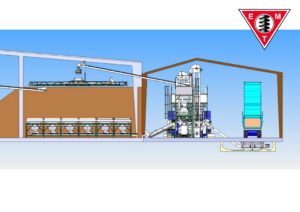

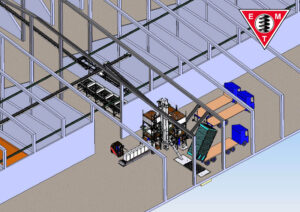

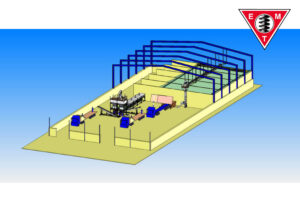

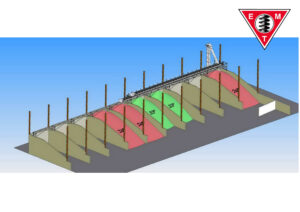

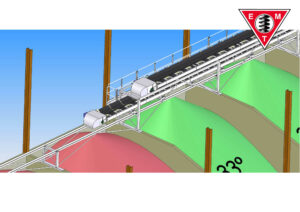

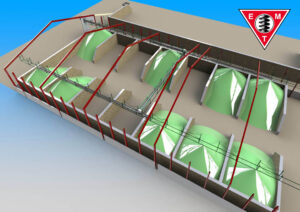

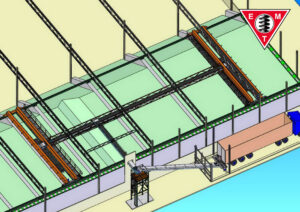

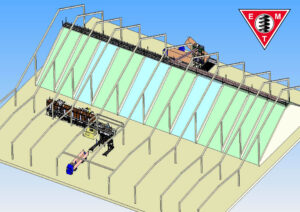

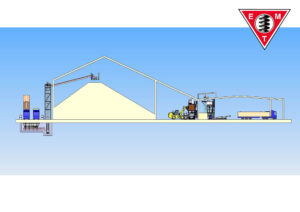

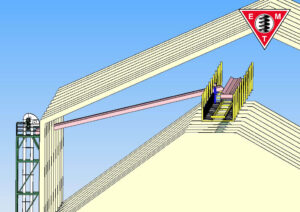

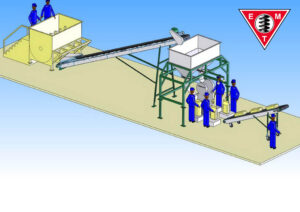

The shuttle conveyor box filling unit is designed to fill warehouses with bulk material as effectively as possible. By using a shuttle conveyor, the complete warehouse can be filled from above.

The shuttle conveyor box filling setup comes in many forms, depending on the warehouse layout, the required capacity and the specific customer requirements the shuttle conveyor box filling unit is designed specifically for your situation.

Features

Capacity up to 200 t/h.

Warehouse filling.

Efficient use of expensive floor space.

Automatic control

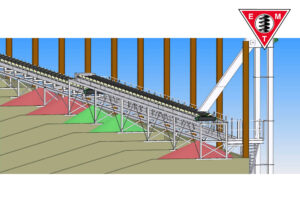

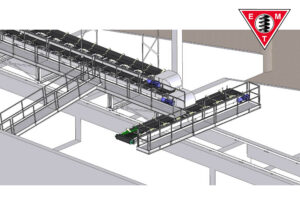

The setup can be placed on top of box filling walls or hanged from the roof. The machines usually start with an intake hopper, followed by transport up to the warehouse. From the centre of the warehouse the shuttle conveyor distributes the fertilizer across the required boxes. Possibly extra distribution conveyors are added that can fill the boxes across the entire length to increase the capacity.

The complete unit can be automatically controlled from the HMI or by remote control.