Bagging solutions

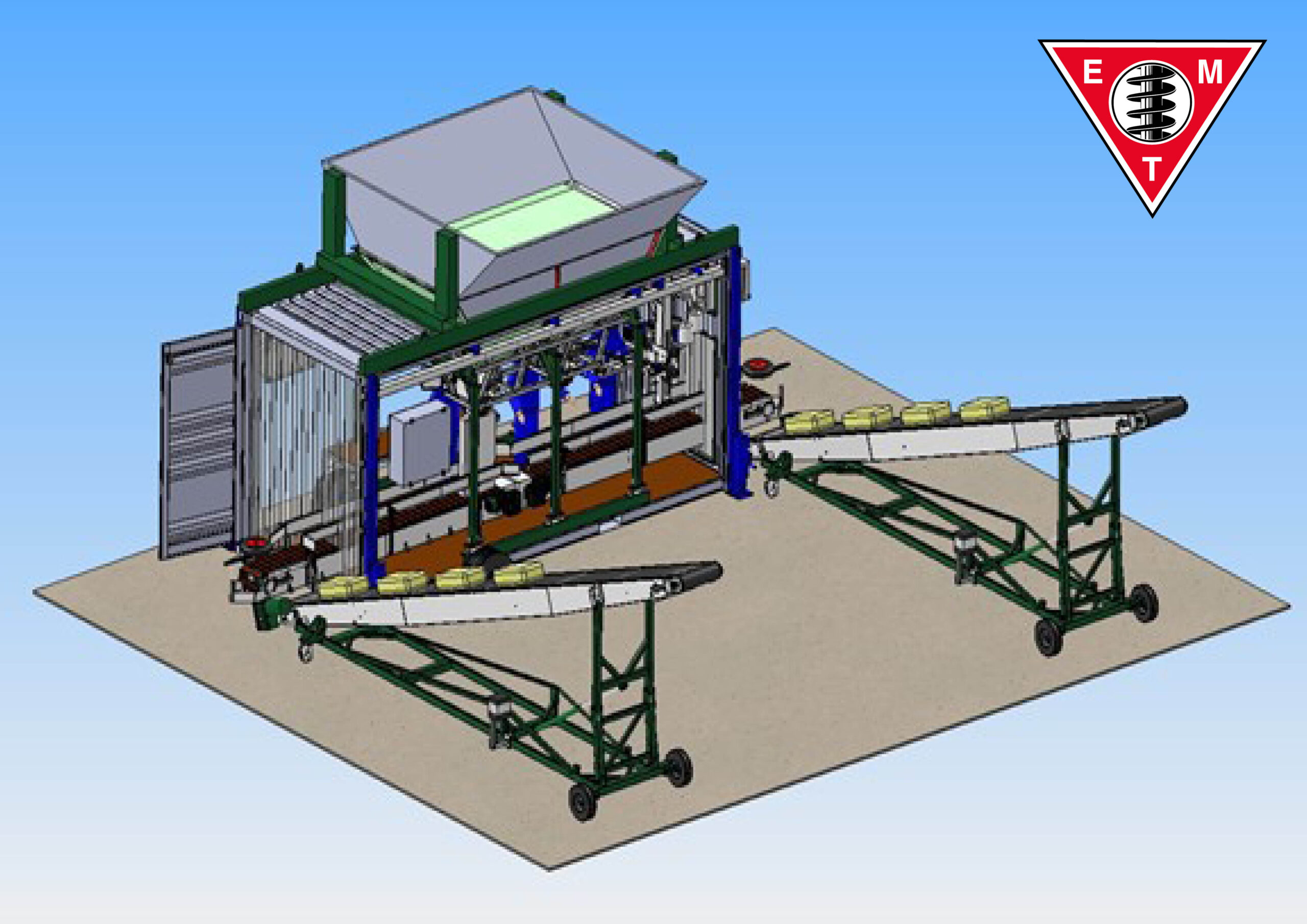

Two separate bag fill lines that are completely integrated in 1 normal 20ft (6 meter) container. The container has door openings on both short sides to bring the bags out. The complete line is portable and can be moved, to any decided place, by ship/truck. The load out conveyors and compressor are loaded separately. When necessary, in a second container. The machines need to be placed on the flat floor by a crane or forklift. Assembly of the container bag line is easy to do.

Contact usFeatures

In one 20ft (6 meter) Container.

25 to 50kg bagging

40 tons with 50kg bags and 20 tons with 25kg bags.

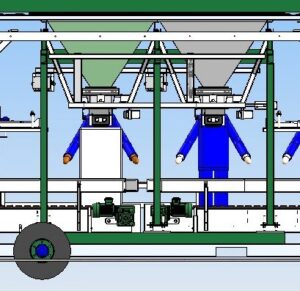

Under each of the two valve units, a gross bag weigh scale is mounted.

Containerized Gross/Nett Bagging

Revolutionize Your Fertilizer Packaging with EMT’s Advanced Containerized System

EMT is thrilled to unveil an innovative solution tailored to enhance the efficiency and precision of your fertilizer bagging operations. This isn’t merely a machine; it’s a comprehensive, containerized system crafted to elevate your packaging process to new heights.

Highlight Features:

– Precision Weighing: Our system incorporates dual Gross/Net weighing mechanisms within the container, facilitating exact product measurements. This allows for customizable bag contents and quantities through an intuitive HMI interface.

– Simplified Operation: With a straightforward button press, operators can initiate the bagging sequence. A unique bag clamp, activated by sensor touch, ensures secure bag placement for both rapid and meticulous filling phases, guaranteeing precise bag weights.

– Efficient Bag Management: Post-filling, bags are automatically directed to a sewing or sealing unit for closure (additional equipment quoted separately), streamlining the packaging process.

– Enhanced Productivity: The system is designed for operational efficiency, requiring just two operators per line—one for filling and another for sealing. With two lines per container, a four-operator team can achieve optimal productivity.

– Flexible Discharge Options: Depending on your operational needs, filled bags can be removed at ground level, elevated to a convenient height, or lifted to truck-loading height at the conveyor’s end.

– Durable Design: Encased in a standard 20-foot container, our robust system is constructed from painted mild steel and equipped with accessible doors for both functionality and security.

Comprehensive System Components:

1. Stainless Steel Hopper: Boasting a 3,000-liter capacity, our easily installed hopper includes a protective rain roof and is made from durable stainless steel, supported by a sturdy frame.

2. Valve Units: Designed for free-flowing products, our pneumatic valve units ensure accurate dosing and are strategically placed beneath the weigh scales.

3. Electronic Weighing Systems: Offering unparalleled precision with a maximum 60 kg capacity and a 0.5% tolerance, these systems guarantee consistent product dosing.

4. Pneumatic Cylinders: The entire operation is smoothly managed by stainless steel cylinders, powered by electro-pneumatic valves for seamless functionality.

5. Gravitation Filler: This stainless steel component, perfect for open bags, fills bags efficiently and transitions them automatically to the conveyor.

6. Control System: A dedicated electrical panel oversees the filling operation, with settings for both automated and manual control to suit various operational preferences.

7. Wiring Included: All necessary electrical cables and support trays are pre-installed, ensuring a turnkey solution ready for immediate use.

Specifications:

– Engineered for demanding environments, with all product-contact surfaces made from Stainless Steel #304.

– The container’s mild steel body is sandblasted and double-primed for lasting durability.

– The system is powered by a Wago control PLC and Penko weigh indicators for precise operation.

Transform your fertilizer bagging process with EMT’s state-of-the-art containerized system, designed for accuracy, efficiency, and durability. Contact us to learn more about how we can assist in optimizing your operations