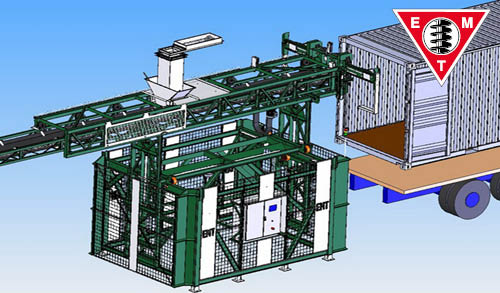

Auxiliary machines

A container on a truck can be (automatically) filled with the help of a conveyor that can be moved horizontally in and out of that container. The conveyor will go inside (to the end of a 20 ft container and 3/4th into a 40ft container), start to load and gradually retracts until the container is fully loaded.

Capacity is approx. 100-120 m3/hour. The support structure must be mounted to the ground.

The Main Features

Sea container filling

20ft & 40ft containers.

Capacity 100-120 m3/hour.

How does it work

The truck driver backs the truck with the container up towards the horizontal container filler. The driver warning light tells the driver where to stop. At that point, there is enough room for the driver to open the doors of the container and to prepare the container for the filling.

The operator starts the unit to semi-automatically (with the remote control) lock the conveyor frame onto the hook blocks of the container.

When the conveyor is locked, the operator pushes the Start button on the remote control to start the automatic filling process.

The conveyor frame will go automatically to the backwall of the container or its outmost position and starts filling on the left side of the container. When the machine detects product, it will automatically start moving slowly. While filling the conveyor will zig zag back towards the opening of the container.

Depending on the kind of suspension of the truck, the conveyor frame can be tilted to ensure the container will be filled to the desired level.