Ballance

Factory project

Advanced fertilizer blending line for bulk loading in New Zealand

FIND OUT ->

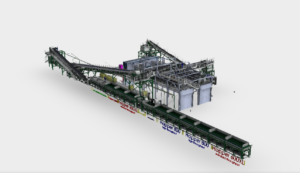

EMT Installs a 240-ton – 315 m3 per hour fertilizer blending unit at Ballance – New Zealand.

In the first quarter of 2023 EMT has finished the installation of a 315m3 blending machine at Ballance in New Zealand, located in Whangarei New Zealand, Designed and produced in the Netherlands and transported to the other side of the world via 15x40ft sea containers.

Both the mechanical and electrical design, as well as the software, were developed internally at EMT. Also under the guidance of EMT personnel the machine was professionally assembled on location.

Check out the Ballance video tour

Click on the video below to see the tour of the Ballance factory and the advantages they have with the new factory.

Fertilizer blending

The 17-hopper Weighcont blending machine that was installed at the Ballance Whangarei Hub consists of 9 weighing hoppers, each with 2 dosing belts, among other components. A product is assigned to each hopper, which ends up on a central conveyor via the dosing belts. These hoppers are filled with a large bucket shovel. After the double hoppers, there are 8 hoppers with a single dosing belt that can be filled with product from Big Bags or small bags of 25 to 50 kg.

The central conveyor belt transports the product to a coarse sieve where lumps are removed from the product stream and are broken back to the correct size by a lump breaker, so that no product is lost. After this conditioning of the product, it is transported to the 2 parallel loading lines. There, the product can be loaded in bulk into 48 ton trailer trucks, capable of carrying 24 tons with an additional trailer of 24 tons behind.

These combinations are fully filled using a movable transport system above the trucks. Alternatively, the product can be filled in Big Bags or small bags, so it can be transported in bags to the farmer or distributor.

Accuracy, efficiency, and consistency

The decision to choose a weighcont blender for the Ballance project was driven by the need for accuracy, efficiency, and consistency in the mixing process.

With multiple weighing hoppers that each can be filled directly as the raw materials are received (bulk, big bag, small bag) warehouse handling efficiency is ensured. The weighcont blender provides a high level of precision in ingredient measurement and dispensing.

The coarse sieve and conditioner ensure that the product is properly conditioned and free of lumps, leading to a uniform mix.

Overall, the weighcont blender is an ideal choice for the Ballance project, delivering high-quality results with minimal waste or errors while still maintaining a high tonnage up to 250 ton per hour.