Coating solutions

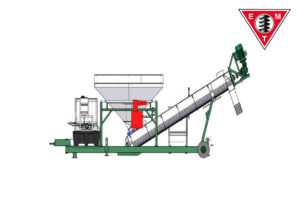

The mild steel support frame constructed of heavy-duty tubular steel with wheels is the basis for this design. On top of the support frame a stainless-steel weighing hopper with a blending screw and liquid adding unit are placed. Due to the two wheels, the frame is movable with the help of a forklift with a hitch.

Contact usThe Main Features

Inhibitor impregnation

Capacity 120 mᵌ – 80 ton per hour 6 meter blend screw.

Portable machine on wheels.

The bulk material will be discharged through a weighing hopper, the weighing hopper is extra wide to allow for front end loaders to easily discharge into the hopper. The flow from this hopper is operated by a slide and will control the output of the material through the loss in weight system.

From the hopper the material will enter the blending screw, this extra-long 6m screw is designed to blend granular material with liquid or powdery material. The extra length of the blend screw allows for a longer blending duration, giving the product more time to blend. At the beginning of the screw a separate inlet is installed that will facilitate the input of liquid product.

Close to the blending screw a pump will be installed that pumps the material from an IBC or tank. The IBC or tank is placed on a weighing scale and through the same loss in weight technique it is possible to measure the exact flow of material entering the screw.

The complete system operates on a state-of-the-art software system that is user friendly and intuitive to use. The software system on a standalone unit runs on the HMI in the electrical panel.

Contact us