Coating solutions

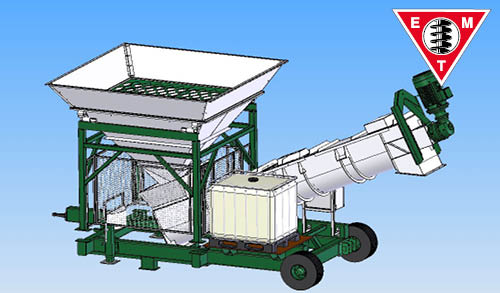

The mild steel support frame constructed of heavy-duty tubular steel with wheels is the basis for this design. On top of the support frame a stainless-steel weighing hopper with a blending screw and liquid adding unit are placed. Due to the two wheels, the frame is movable with the help of a forklift with a hitch.

Contact usThe Main Features

Inhibitor impregnation

Capacity 200 mᵌ – 150 ton per hour.

Portable on wheels.

The bulk material will be discharged through a weighing hopper. The flow from this hopper is operated by a slide and will control the output of the material through the loss in weight system.

From the hopper the material will enter the industrial size blending screw. This screw is designed to blend large amounts of granular material with liquid or powdery material. At the beginning of the screw a separate inlet is installed that will facilitate the input of liquid product.

Close to the blending screw a pump will be installed that pumps the material from an IBC or tank. The IBC or tank is placed on a weighing scale and through the same loss in weight technique it is possible to measure the exact flow of material entering the screw

The complete system operates on a state-of-the-art software system that is user friendly and intuitive to use. The software system on a standalone unit runs on the HMI in the electrical panel.

Contact us