Blending solutions

The Smithbuilt machine processes all raw materials into an excellent blend and is suitable for granular fertilizer production.

The stainless steel Smithbuilt single unit is build for low volume production in space-confined areas.

When the machine has produced a blend it can be transported to a bag filling station.

The Main Features

Capacity per charge of 4,5 – 5,5 ton/m³

Capacity per hour 20 to 30 ton per hour.

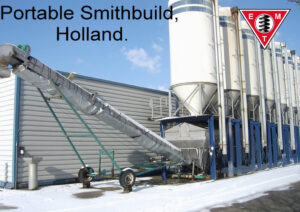

Easy to install and portable machine.

Open top design.

The Smithbuilt has a round internal blending baffle for a perfect blending flow. When the machine is fully opened it will be filled by a loader. All raw materials will be blended in the blender body by the fast turning of the blending screw. The blending process takes 3 minutes. The manual discharge gate will open and the materials will flow out of the machine on a transport conveyor. The auger inside the blender is made of mild steel. It is placed in a stainless steel tube and has a bottom bearing. A steel screen to catch lumps has been mounted on top of the blender. The slide gate beneath the blender can be opened manually.

The blender motor with gearbox has a manually operated on/off switch integrated with a thermo safety switch. The machine is mounted on four stainless steel legs. Beneath these legs a mild steel weigh frame has been mounted. It has four load cells and an indicator with a large display.

The blend capacity of the Smithbuilt is 4,5 or 5,5 metric tons per batch; the total capacity is 20-30 ton/m³ per hour.

This product can be adjusted to customer demands.

Contact us