Blending solutions

The Weighcont -weighing continuous- blender is suitable for powder and granular fertilizer production. The machine processes all raw materials into an excellent blend. When the machine has produced a blend, it can be transported to a bag filling station.

CONTACT USThe Main Features

Capacity from 10 to 120 ton per hour (standard machine)

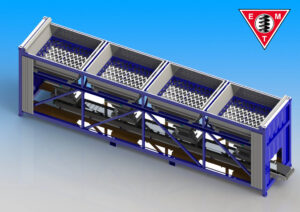

Maximum 5 hoppers, full automatically blender line.

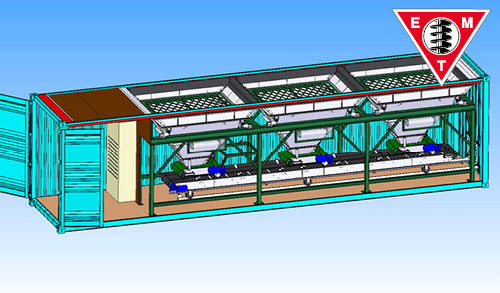

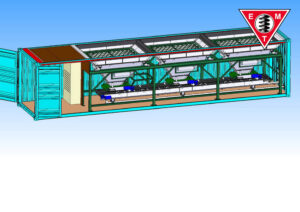

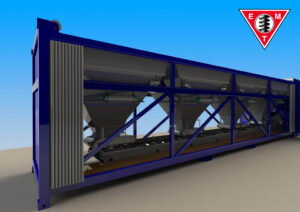

The machine is integrated in a container and movable by normal trailer.

Computercontrolled.

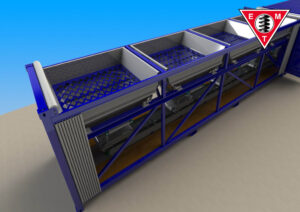

Weighing Fertilizer Blender in a Container of 40 foot – 12 meter

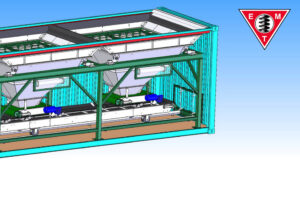

This blender operates with the most modern technologies. The Weighcont blender consists of two or more stainless steel hoppers. The computer commands and controls the entire continuous weighing and blending process by means of a variable electro or hydraulic system. The raw materials are metered by stainless steel metering conveyors. Every hopper is mounted on a digital weigh system.

This system makes automatic dosing metering corrections. This guarantees an accurate flow of materials through the conveyor at the rate required. The dosing metering conveyor discharges the materials to a central transport conveyor. The hoppers have open tops that can be filled with a loader or a forklift. The whole machine can be operated from a single pc computer or it can be network connected. This gives the operator complete control on the quality of the blending materials.

Every hopper has a large display that provides information about the type of materials and the actual weight of the material in each hopper. While blending, the hoppers will discharge the product simultaneously, meaning all materials will be transported to the central transport conveyor at the same time. If necessary an extra blend auger can be installed on which the central belt conveyor discharges the material.

The machine can be produced with a maximum of 5 hoppers with a capacity of 5 ton per hopper.

The number of raw material components depends on the number of hoppers.

This product can be adjusted to customer demands.