Coating solutions

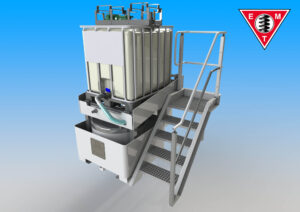

The containerized liquid coating unit is especially constructed so that the complete machine is installed in a 20ft/6 m container with stainless steel feed tank and a flooded suction pump and works on 2 x weight system information to check the flow of the product and liquid flow and blending screw auger.

The weight hopper is integrated in the container and the blending screw auger can be pulled on a specially constructed support frame.

The Main Features

Capacity from 10 to 120 ton per hour

Portable in container

Easy installed on any desired place

Filled via a 5 m³ stainless steel hopper with extension to give greater clearance for the crane filling mechanism, this is then covered by a tent harmonica roof.

This feeds an Screw Auger at an angle of 20°, this is fed via an electrically operated slide valve, the valve and associated system can give an accuracy of between 10 tonnes per hour and 120 tonnes per hour via full inverter drive.

This solid handling is complimented by the addition of liquid from the pump system, this too has full inverter control across the range of production. All of the pumps valves and equipment are housed in a stainless steel bund sized for 125% of the maximum volume and has a level alarm should a spill even begin to appear.

The liquid is topped up via a 1 meter cubed IBC (intermediate bulk container) which is located on a tipping bed, so that when the container is low on product, the container will tip up via springs to empty the last of the liquid into the system.

All of this equipment is stored inside a 20 foot container.

The container top is closed by a flexible cover seal (like trailer covers).

Contact us