Big bag solutions

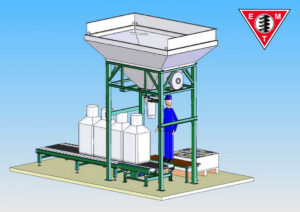

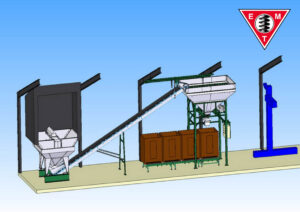

The big bag Low Profile is constructed to fill FIBC bags (Flexible, Intermediary, Bulk, Containers) and is portable.

Contact usCompact design

Portable machine, movable by normal trailer.

40 to 50 T/ph

Capacity 40 ton per hour with bags of 1000 kg, or 50 ton per hour with bags of 500 kg.

Powder and granular

Suitable for powder and granular materials

Automatic or manual

Machine can operate automatic or manual.

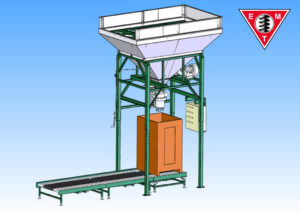

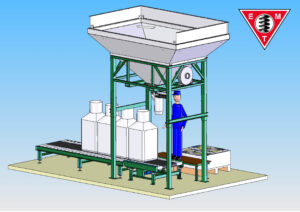

Big Bag low profile portable

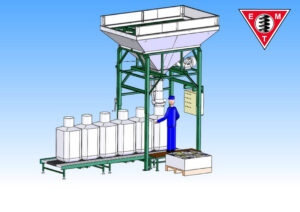

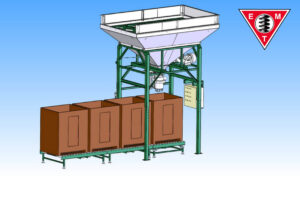

Our portable big bag fill machine is designed to automatically weigh and efficiently fill bags ranging from 100 to 1250 kg, making it suitable for both powder and granular materials. The storage hopper is supported by four sturdy H-profile legs and the hopper is constructed of stainless steel to ensure durability. Positioned beneath the storage hopper is a pneumatic valve with both large and fine openings. This valve facilitates the unloading of materials into a stainless steel pipe that connects to a large bag.

The big bag is placed on a platform scale or roller scale on the floor, the platform or roller scale determines the weight of the product.. The height of the filling pipe can be adjusted over a length of 400 mm. It’s necessary to manually put on the big bag and securely close it around the filling pipe. Before the filling process commences, a blower is used to inflate the bag with air. As the bag reaches its full size, the materials flow into it.

Once the bag is filled, a roller conveyor transports it away from the filling pipe. The scale system utilizes an Avery Salter Weightronix weigh indicator. The entire unit can be operated in either automatic or manual mode.

The machine incorporates pneumatic stainless steel and fiberglass cylinders to facilitate its operation. It offers various setup possibilities to cater to different requirements. The ‘big bag Low Profile’ configuration is a portable big bagging machine that can be easily moved with a forklift and loaded into a standard trailer for transportation to different locations. It can be conveniently filled directly into the hopper using a loader.

With a hopper height of 4000 mm, the system has a capacity of 40 tons per hour when using big bags weighing 1000 kg, or approximately 50 bags weighing 500 kg per hour. Furthermore, this product can be customized to meet specific customer demands.