Bagging solutions

The big bag High Speed is constructed to fill big bags with a capacity of 60 tons per hour. The machine automatically weighs and fills bags of 100 to 1250 kg. This machine is suitable for powder and granular materials. The whole machine is standing on four support legs.

Contact usThe Main Features

High capacity for filling big bags

50 to 60 tons per hour

120 Bags per hour

Big Bag High Speed Twin

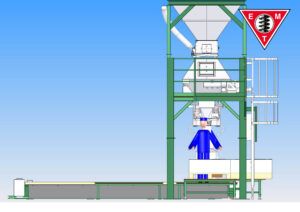

The Big Bag High Speed machine is purpose-built for efficiently filling FIBC bags (Flexible Intermediate Bulk Containers). This advanced big bagging machine automatically weighs and fills bags ranging from 100 to 1250 kg, making it ideal for handling various powder and granular materials. The machine is supported by sturdy four support legs, with a weighing scale mounted on these legs to ensure accurate measurements. The scale hopper, which utilizes a load cell, is positioned beneath the storage hopper.

Mounted under the storage hopper, there are two pneumatic half-moon valves specifically designed to fill the scale hopper. The dosing operation, which can utilize either a large or fine valve, is automated based on the position of the slide. The weighing scale hopper unloads the material into a stainless steel pipe, fitting into the big bag. The scale system operates seamlessly with an Avery Salter Weightronix weighing indicator. Notably, the big bag fill machine efficiently weighs the material without directly measuring the bag weight.

The whole unit offers both automatic and manual operation modes to cater to diverse requirements. The Big Bag fill machine is positioned above a dedicated big bag conveyor. Prior to the filling process, the big bag is manually held up and securely closed around the filling pipe. The filling pipe is adjustable in height over a length of 400 mm, ensuring flexibility. To ensure proper bag inflation, a blower is employed to blow air into the bag until it reaches its full size. During the filling process, a second blower effectively removes excess pressurized air, which is then directed into a dust reducer. This innovative system prevents the release of dust during the filling process, ensuring a clean working environment.

Once the big bags are filled to capacity, they are conveniently placed on the big bag conveyor, which efficiently transports the bags away from the machine, streamlining the workflow.