Bagging solutions

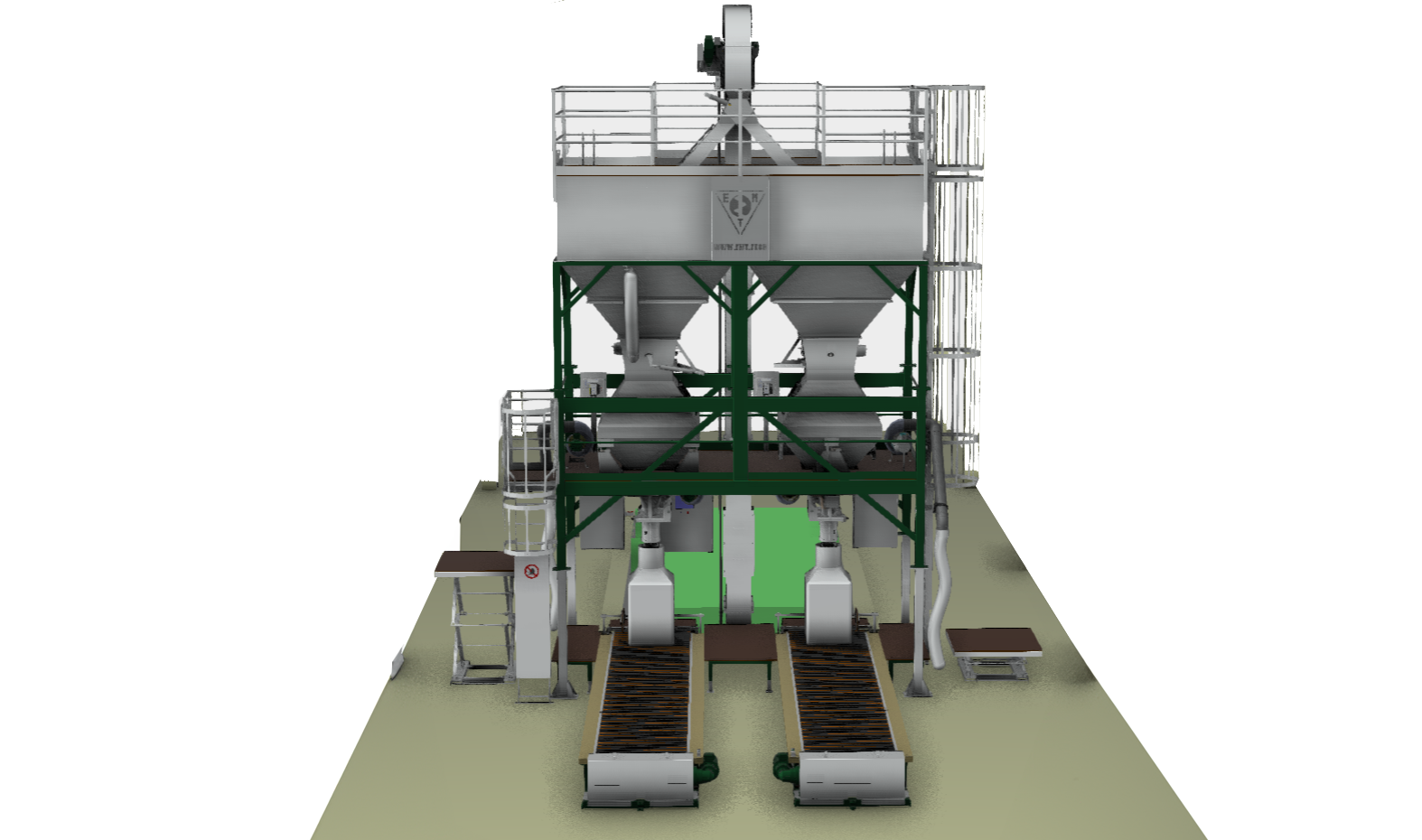

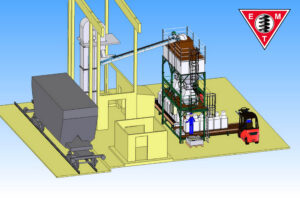

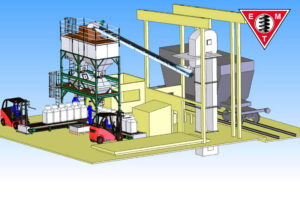

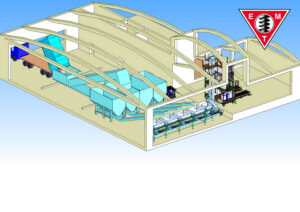

The big bag High Speed Twin is constructed to fill two lines of FIBC bags at the same time. The machine automatically weighs and fills bags of 100 to 1250 kg. This machine is suitable for powder and granular materials.

The whole machine is standing on four support legs.

The Main Features

High capacity for filling big bags up to 240 bags from 100 kg to 1250 kg. 100 to 140 ton/m³ per hour.

Suitable for powder and granular materials.

Two weighing scale hoppers in one construction frame and Two discharging big bag conveyors.

Big Bag High Speed Twin

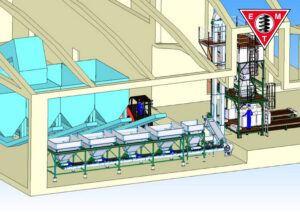

Two stainless steel weighing scales are mounted in the machine frame, the storage hopper also stands on these legs. The two scale hoppers are mounted on load cells which are located under the storage hopper.

Under the storage hopper there are also mounted two pneumatic halve moon valves which fill the two scale hoppers.

When dosing the product, a large or fine opening can be used. This operation is done automatically by pneumatic cylinders.

The weighing scale hopper unloads into a stainless steel pipe that fits into the big bag. The scale system operates with an Avery Salter Weightronix weighing indicator. The machine weighs the material without weighing the bag.

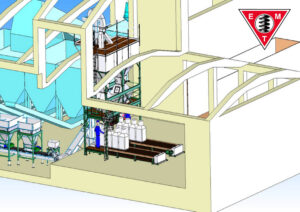

The whole unit operates automatic and manual operation is also possible. The big bag High Speed Twin is located above two big bag conveyors that transport the bags away from the filling pipe. Before the filling process starts the big bag is held up and manually closed around the filling pipe. The filling pipe is adjustable in height over a length of 400 mm. that makes the filing of different bag sizes possible. Before the big bag will be filled, a blower will blow air into the bag until the big bag has its full size.

During filling, a second blower takes out the over pressured air and this air is blown into a dust reducer bag. By using this system, no dust comes free during the filling process. When the big bags are full, (they are placed on the big bag conveyor during filling) these conveyors move the bag away from the machine.

The big bag High Speed Twin has a capacity of 200-240 bags of 500 kg per hour and a capacity of 100-140 bags of 1000 kg per hour.

This product can be adjusted to customer demands.