Auxiliary Machines

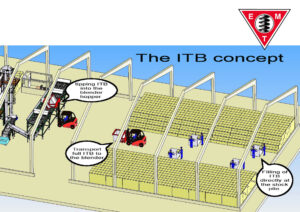

intermediate tipping bucket is an alternative way to fill your blending line directly from (small or big) bags without requiring expensive bulk conveyors or front loaders. Furthermore, you prevent unsafe work situations like working at height. In short, the most efficient way to fill your blending line from bags in low labour cost countries.

Contact usFeatures

Cost effective.

Easy capacity scalable.

Fits on local forklifts.

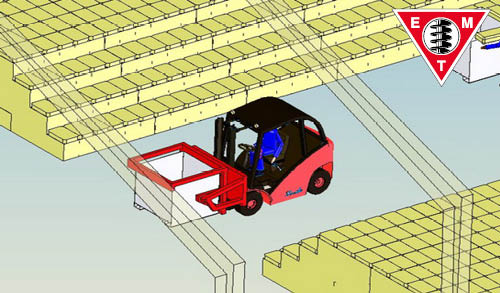

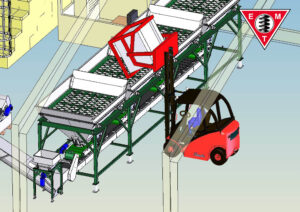

The Intermediate tipping bucket consists out of two parts. The unique front-end tipping frame and robust stainless-steel containers fitted for the tipping frame. The fertilizer can be discharged from the bags directly in the container. Multiple containers can be filled at the same time, the front-end tipping frame connected to your local forklift is used to lift up the buckets and safely discharge them into the blender hoppers. One tipping frame can be used to discharge multiple containers in sequence.

Benefits of the Intermediate tip bucket (ITB)

Compared to the box fill conveyor, working in this way, has the following benefits:

1. It is cheaper

Buying more ITB’s is a lot cheaper than the investment in boxes and a box fill conveyor.

Investment of normal forklift of 3 ton and a lift height of minimum 3,5 meter.

No investment needed for a bucket loader or a reach arm loader.

1 x investment of a normal pickup bucket when there is a bulk storage of product (not really needed, but recommended.)

2. Better product

Less bag handling

Less product handling

Less attachment of moisture to the fertilizer product.

3. The location of the blending and/or bagging line and the storage of bags or bulk products, becomes more irrelevant

More distance possible between stock pile storage and blender line.

The bag storage can be outside or in another warehouse.

Blender line and bagging can be installed in a separate warehouse.

4. More efficiently

Because there is no space needed in the warehouse for the conveyor and boxes, this space can be used for bag storage.

The operator has to lift the bag only once: from the stock pile to the ITB.

Empty bags are separated. They stay in the stock pile area.

(Bags quality difference).

More save work, no high lifting of the bags by a forklift to the conveyor.

Less concentration of people at the box fill conveyor and no movement control for the conveyor.

5. Upscaling capacity

It is easy to upscale capacity by using more ITB’s – an extra forklift or more operators.

The usage of more ITB’s per product is also possible.

This solution is a very good alternative for intermediate boxes and a box fill conveyor.