Bagging solutions

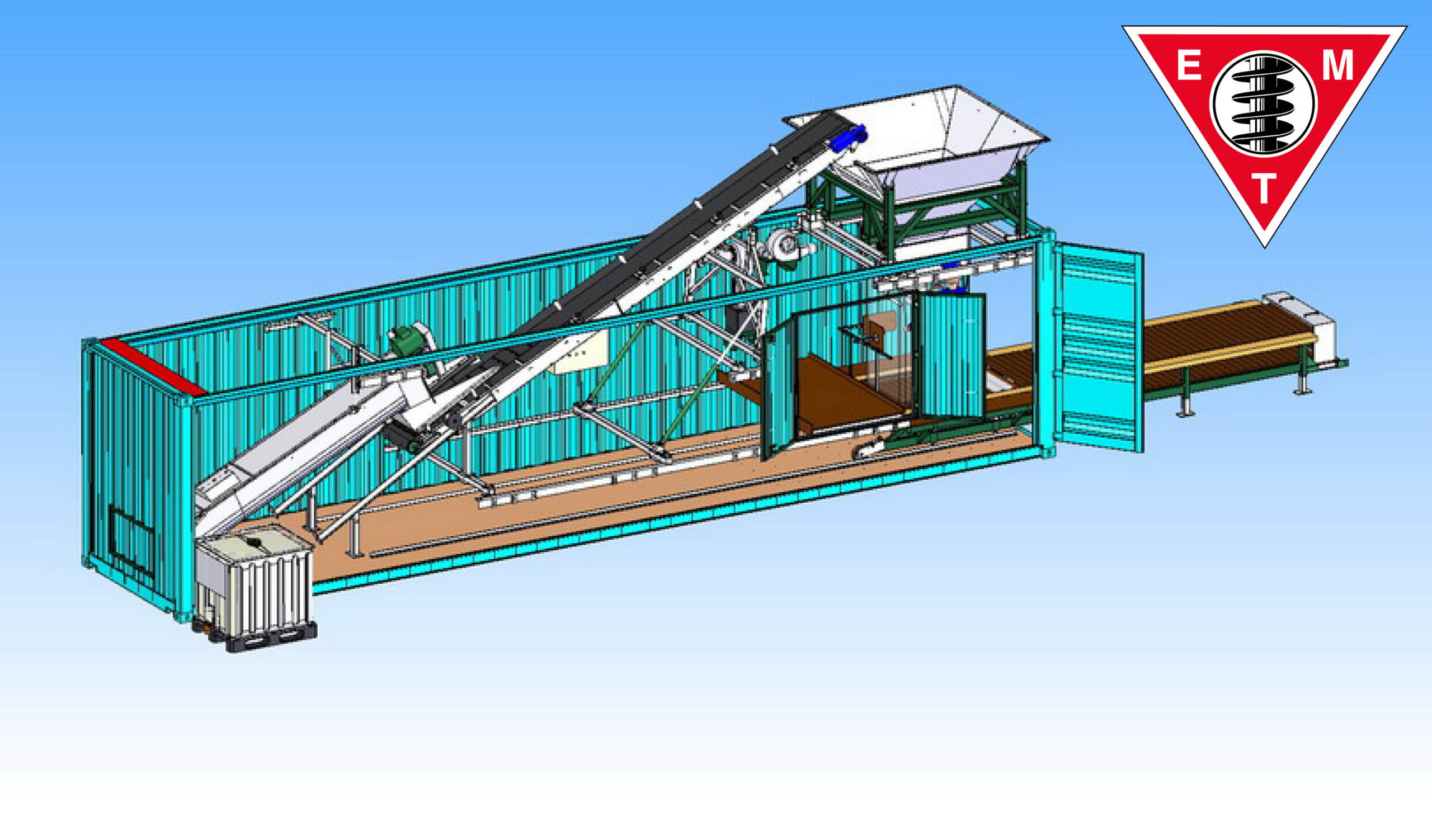

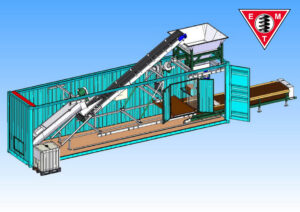

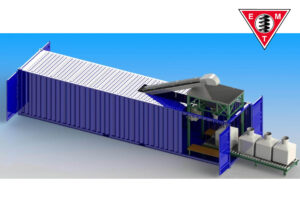

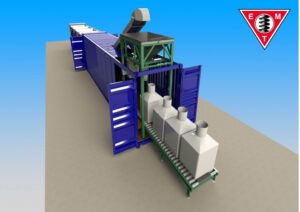

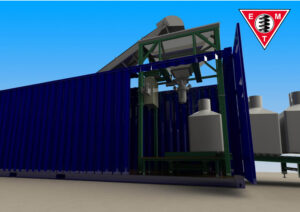

Presenting our Big Bag Filling Machine, designed specifically for filling FIBC bags (Flexible, Intermediary, Bulk, Containers) and Jumbo Bags. This machine is seamlessly integrated within a 40-foot (12 m) container, making it a compact and versatile solution for your filling needs.

With a capacity of 45 tons per hour, our Big Bag Filling Machine is a powerful tool.

Built with durability in mind, our Big Bag Filling Machine is constructed from high-quality materials that ensure long-lasting performance. And with its user-friendly interface, it’s easy to operate and maintain, allowing for maximum productivity and efficiency.

The Main Features

Standard portable container vertical installed.

One big bag weighing hopper is integrated in the container, the same as the big bag High Speed.

Capacity 45 ton per hour, 90 big bags of 500 – 600 kg per hour and 45 big bags of 1000 to 1500 kg per hour.

The machine automatically weighs and fills bags of 100 to 1250 kg. This machine is suitable for powder and granular materials. The storage hopper stands on four H-profile legs. The materials are put into the storage hopper which is constructed of stainless steel. A pneumatic valve has been mounted under the storage hopper. This valve has a large and a fine opening. The hopper unloads into a stainless steel pipe that fits into a big bag. The big bag is standing on a platform scale or roller scale on the floor. The height of the filling pipe is adjustable over a length of 400 mm. The big bag must be held up and manually closed around the filling pipe. Before the filling process starts, a blower will blow air into the bag. When the bag has its full size, the materials flow into the bag.

The platform or roller scale will determine the weight of the product. When the bag is full, a roller conveyor transports the bag away from the filling pipe. The scale system works with a weigh indicator of Penko.

The whole unit can be operated automatic or manual.

The unit operates with pneumatic stainless steel and fiberglas cylinders.

The hopper can be filled with a conveyor or with a loader directly into the hopper.

Before operation the Big Bag filling unit should be lifted up by forklift. So the hopper of the Big Bag Unit will stick out of the container roof.

This product can be adjusted to customer demands.