Bagging solutions

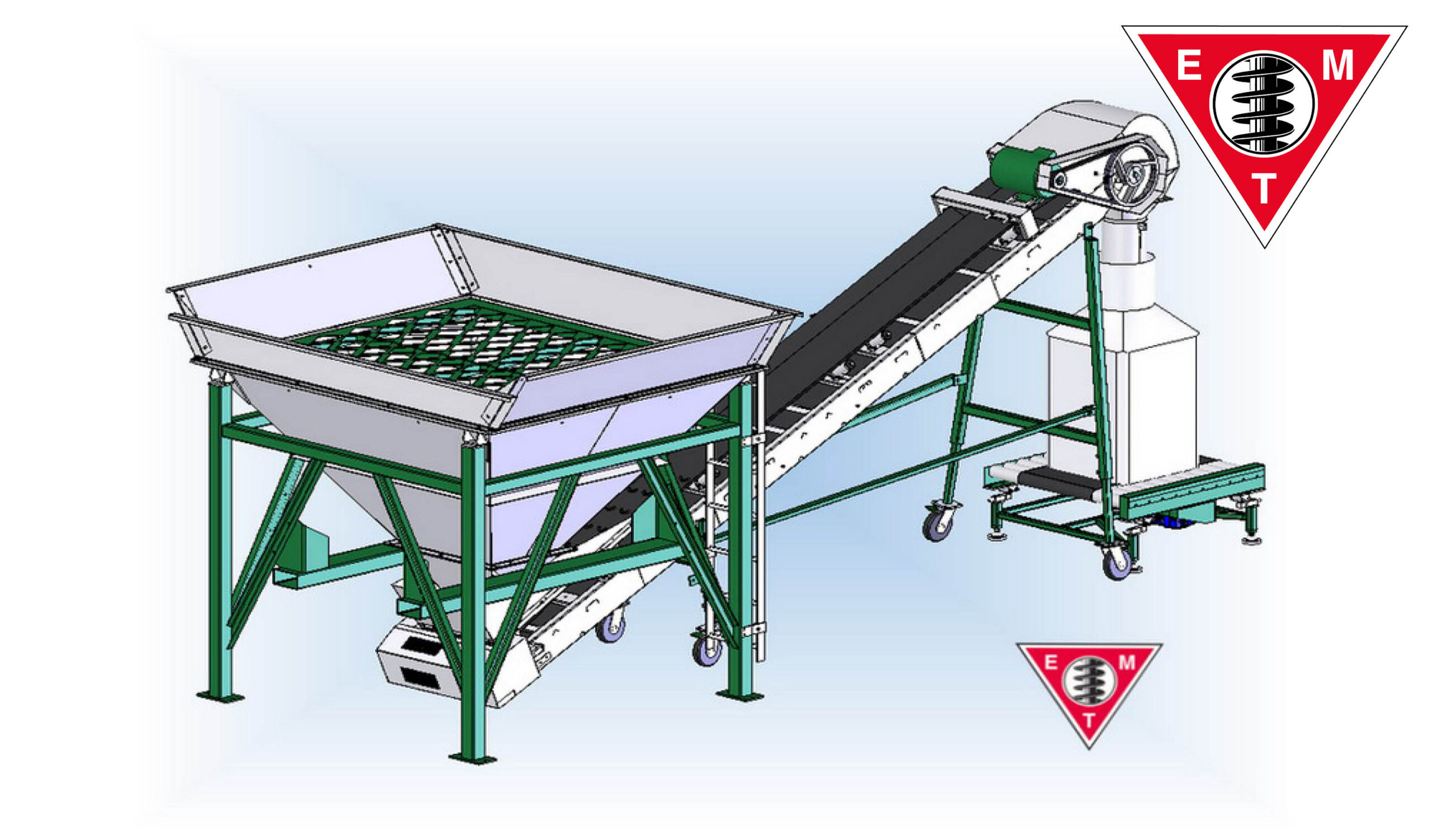

Introducing the Big Bag Fill Control Unit – the perfect solution for those looking to streamline their bag filling process. This machine is equipped with a belt conveyor and scale, designed to ensure accurate and efficient filling of big bags.

Contact usThe Main Features

The unit is specially built for an aggressive surrounding

All parts like bolts, nuts, etc. are made of Stainless steel #304.

Compact machine set up.

The unit can run automatically and by hand.

Big Bag Fill Control Unit by Belt, Conveyor and Scale.

The conveyor belt is made of high-quality stainless steel, and is installed on a sturdy mild steel support frame. At the discharge end of the belt, a round pipe with a diameter of 250mm is installed, which can be adjusted in height to suit the bag type of the customer’s choice. The height of the pipe and the driven roller conveyor can be customized before production, ensuring that the system is perfectly tailored to the needs of your business.

In addition to its conveyor system, the Big Bag Fill Control Unit also includes a ventilator to blow air into the big bag before filling, as well as an electrical control panel for easy operation. The bag is kept in place at the fill pipe by a hand-operated bag clamp, and an electrical weigh unit under the bag ensures that the correct amount of product is added.

Dosing is done in two stages, with the machine first using big dosing to quickly fill the bag, before switching to fine dosing to ensure that the correct amount is reached precisely.

This is done by a cylinder placed under the conveyor outlet, just above the bag inlet. Before filling can begin, a compressor is needed to fill the bag with air, ensuring maximum efficiency.

The belt conveyor is designed to start and stop automatically according to the weight information of the platform roller scale, and an electrical panel mounted at the side of the bagging machine controls the entire bagging operation. With a weighing capacity of up to 2000 kg, this fully-automatic system is the solution for fast, accurate and efficient big bag filling.